Wednesday, 15 August 2012

Welding Filler Metal Rods And Fluxes

Do you like this story?

Filler metal:

Filler metal:

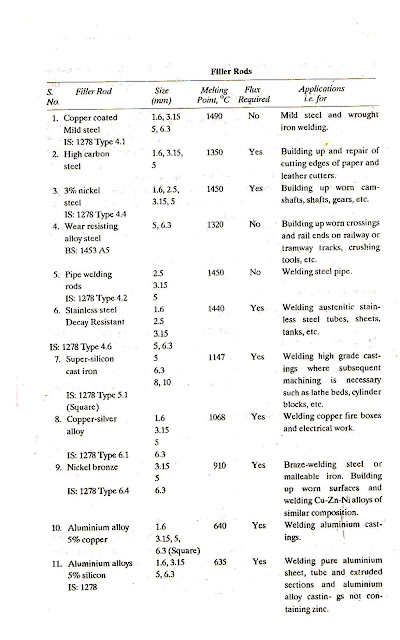

It is the material that is added to the weld pool to assist in filling the gap or groove. Filler metal forms an integral part of the weld. Filler metal is usually available in rod form. These rods are called filler rods. Filler rods have the same or nearly the same chemical composition as the base metal. Welding filler rods are available in a variety of composition and sizes. Some of them are given in the table below:

Flux:

During welding if the metal is heated or melted in air, oxygen from the air combines with metal to form oxides which result in poor quality, low strength weld or in some cases may even make welding impossible. In order to avoid this difficulty, a flux is employed during welding. A flux is a material used to prevent, dissolve or facilitate removal of oxides and other undesirable substances. A flux prevents the oxidation of molten metal. Flux may be used either by applying it directly on the surface of the base metal to be welded or by dipping the heated end of the filler rod in it. The flux sticks to the filler rod end. No flux is used in the gas welding of steel.

- Flux for welding cast iron: Fluxes for gray iron rods usually composed of borates or boric acid, soda ash and small amounts of sodium chloride,etc.

- Flux for welding stainless steel: Flux may contain compounds such as borax, boric acid, fluorspar, etc.

- Flux for welding aluminium and its alloys: The flux may be applied on the base metal by brushing and on the filler rod end by dipping the same into the flux paste just before welding. Fluxes employed for welding aluminium and its alloys are compounds of lithium, sodium and potassium and are obtainable in either paste or powder form.

- Flux for welding copper and its alloys: Flux is not necessary for gas welding of pure copper, however for copper alloys, borax based fluxes may be used.

- Flux for welding magnesium and its alloys: Flux must be applied to all edges to be welded and to the welding rod when welding magnesium and its alloys. A flux may contain sodium chloride, potassium fluoride, magnesium chloride, barium fluoride.

- Fluxes for welding nickel and its alloys: Gas welding of pure nickel requires no flux. However alloys of nickel such as inconel and monel require a flux to further clean the base metal and to break up the oxides that are formed as a result of the alloying agents. Flux for inconel may contain Ca(OH)2 , boric anhydride.

This post was written by: Sanjay Verma

Sanjay Verma is an experienced mechanical engineer and a lecturer. In this blog he shares his knowledge about various subjects of mechanical engineering. Follow him on Google+