Monday, 20 August 2012

Rotor Construction

Do you like this story?

Types of Rotors:

There are 5 types of steam turbine rotors:

- The built-up rotor

- The integral rotor

- The hollow drum rotor

- The solid drum rotor

- The welded disc rotor

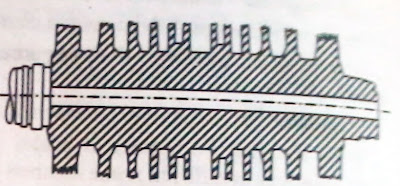

1. The Built-up Rotor:

It consists of forged steel shaft on which separate forged steel discs are shrunk and keyed. It is cheaper since the disc and shaft are relatively easy to forge and inspect for flaws and machining of these components can be carried out concurrently. Its shaft is machined with a series of stepped diameters ending with central collar. Each disc is heated and assembled on the shaft in turn, each being held in position by a form of circlip. Relative rotation is prevented either by keys, or by hub dowels known as buttons, which locate the hubs one to another to the central collar. The number of discs depend upon the number of stages which in turn depends upon the turbine output.

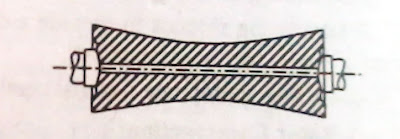

2. The Integral Rotor:

The shaft and wheels of this type of rotors are formed from one solid forging. Integral rotors are expensive and difficult to forge, and there is a high incidence of rejects. Over and above, a large amount of machining time and waste material are involved.

Nevertheless, the advantages are such that the are invariably used for the H.P. (high pressure) rotors on modern re-heat turbines, and sometimes for the I.P. and L.P. rotors as well. Following are the advantages of integral rotors:

- There is no chance of disc to become loose, particularly at high temperature end where at times the wheels may be hot and the shaft pull as found in the built-up rotor.

- This rotor is also free from the effect of creep which may cause the shrink fit of built-up rotor to disappear after a large number of running hours.

- The hoop stress is of lower magnitude as it contains a small hole meant for inspecting the forging.

- There is saving in axial length and reduction in spindle diameter over the built-up type.

3. Hollow Drum Rotor:

This type of rotor promotes even temperature distribution because it is designed with the same thickness of material as the casing.

4. Solid Drum Rotor:

This type of rotors are suitable for cylinders where there are lower temperatures but large diameters, as in I.P. cylinders without re-heat.

5. Welded Disc Rotor:

The last stage disc is the most heavily stressed part of the turbine and this is one of the main problem of L.P. rotor. The centrifugal load of the large rotating blades set up a tensile stress in the rim of disc, and this stress increases with decreasing radius, its maximum value being at the bore of the hub. If the bore is exceedingly small, the hoop stress becomes very less but of there is no hole, the hoop stresses throughout the disc are theoretically halved. Since there is no central hole in welded disc rotor, it suitable for L.P. rotors. It has two main advantages: It is less stressed and no need for large shaft forgings which are expensive and difficult to manufacture. The welding process and subsequent heat treatment should be performed with great attention.

This post was written by: Sanjay Verma

Sanjay Verma is an experienced mechanical engineer and a lecturer. In this blog he shares his knowledge about various subjects of mechanical engineering. Follow him on Google+