Monday, 20 August 2012

Aims and objectives of maintenance:

The purpose of maintenance is to maintain the steam turbine in order to achieve as high a plant availability as possible at the minimum cost. Maintenance of steam turbines used in power station may be classified broadly in three categories:

- Rectification of defects: The defects may or may not be urgent. If immediate repairs are needed, these may be carried out on running limits or the units should be shut down. If the repairs are not urgent, it may be carried out in planned program of future work.

- Planned preventive maintenance on running units: A system of routine maintenance is adopted to prevent the defects and breakdowns. The planning of such system needs careful consideration in order to arrive at the optimum level of maintenance. The actual work content of each maintenance routine can only be determined after experience with the plant over a period of time. After carrying out the preventive maintenance, it is recorded on a record card with full particulars or the items attended.

- Planned preventive maintenance on shut down units: In order to minimize the maintenance cost of shut down units, it is necessary to plan the work to be done carefully in advance so that the duration of the plant shut down is reduced to a minimum. This planning process should start some weeks or months before the shutdown is due to take place.

Steam turbine overhaul:

Following is the sequence of events of a typical turbine overhaul:

- Remove pipe works mounted on turbine and all top half cylinders and covers.

- Remove coupling bolts and bearings covers leaving thrust bearing assembled.

- Measure all relevant blade and gland clearances on the horizontal joints with fillers or tapered gauges.

- Remove the thrust bearings and then the turbine rotors to have a detailed examination of fixed and moving blades and diaphragms gland segments, casings, bearings, bolts,etc. concerning any type irregularities and damages.

- Re-form all gland and baffle segment knife-edge and restore all radial clearances. Examine the bedding of all bearings to journals and measure oil clearances. Check the adhesion of wright metal of journal bearings.

- After cleaning the blade deposits by water washing, chemical washing or blasting process, refit the rotors and measure clearances on the bottom points of glands and blades with lead or plastic strip. Measure similar clearances on the horizontal joint and compare for eccentricity of the shaft in the casing.

- After cleaning the bearings, check the wear down of bearings with the help of appropriate bridge gauge and filler gauges and compare the figures with those taken on the irection of previous overhaul

- Check the alignment of shaft by taking readings on all couplings and also record the level of all journals.

- Refit top half cylinders and before bolting up take a further set of top blade and gland clearances to confirm the concentricity of the rotor within the cylinder.

- Remark the horizontal casing joints and refit all heavy parts. After this, take the readings for final coupling alignment and adjust it if necessary.

- After refitting the coupling bolts, refit the thrust bearings and all other bearing covers.

- Inspect turbine governor gear with stop, throttle and intercept valves.

- Dismantle other accessories and mountings if necessary and inspect service and reinstall these.

- Clean or replace the oil filters and other items of lubricating systems. Replace the lubricating oil if necessary.

- Inspect all the measuring instruments installed on the turbine and replace if necessary.

Also read:

Monday, 20 August 2012 by Unknown · 0

Goto: Page 1

B. Sequence when the turbine is in motion:

- Apply the load gradually.

- Check up the oil pressure going to the bearings and control gear.

- Observe the oil bearing temperature.

- Observe the turbine for any noise, vibration by watching the vibration and other indicators.

C. Sequence when shutting the turbine down:

- Gradually reduce the load to 0.

- Start the auxiliary oil pump and make sure that oil will be supplied to bearings at proper pressure while the turbine is coming to a stop.

- Trip the emergency valve.

- Close the leak off from the H.P glands.

- Stop the supply of cooling water to the condenser.

- Shut down the condensing equipment and open drains on turbine pipings and casings.

- Continue auxiliary oil pumps in operation untill the turbine rotor has stopped.

- Operate turning gear to rotate rotor at about 3-30 rpm for some time.

During operation, it is good practice to keep a log sheet and record the hourly readings of the instruments. Some of the readings which might prove valuable are the following:

Load on the generator throttle, steam pressure and temperature, exhaust pressure, temperature of cooling water entering and leaving the cooler, bearing oil pressure and temperature, the throttle steam flow rate, speed, frequency, vibration level.

The main requirement of steam turbine while in operation are the proper application of oil to the bearings and a continuous flow of cooling water.

Goto: Page 1

Also read:

Construction of Steam Turbines

Maintenance of Steam Turbines

Goto: Page 1

Also read:

Construction of Steam Turbines

Maintenance of Steam Turbines

by Unknown · 0

The following are the sequences of turbine operation:

A. Starting Sequence:

- Application of controlled power illuminates all of the malfunction lights. This provides a check of the malfunction lights before starting the turbines.

- Reset malfunction circuit by operating a reset switch. Malfunction lights go off and all control devices assume the condition for starting.

- Inspect the governor mechanism, till all grease cups and oil where necessary.

- Open the boiler stop valve to permit heating of the line and avoid condensation in the line.

- Open header, separator, throttle and turbine casing drills.

- Start auxiliary oil pump. This has to be stopped when the main oil pump starts delivering oil at normal pressure.

- Adjust middle valve to secure required oil pressure for the bearing.

- Start the circulating water pumps and dry vacuum pumps of the condenser. Operate the condensate extraction pumps as found necessary to remove water during the warming up period.

- Turn on the turbine steam or water seal.

- Turn on the water to the generator oil cooler and other water requiring parts.

- Keep open all the drains ahead of the throttle valve untill all water of condensation has been removed.

- Open the throttle or governor valve quickly to set the rotor in motion.

- In order to check up whether the tripping mechanism operates properly or not and to prevent the turbine from accelerating too rapidly, operate the overspeeed trip valve by using the hand lever as soon as turbine starts rolling.

- Reset the emergency overspeed valve and before the turbine comes to rest, adjust the throttle so that the turbine wheel operates between 200 and 300 rpm.

- While the rotor is in slow motion, observe any rubbing or mechanical difficulty by using a metal rod or listening device.

- As soon as the temperature of the oil leaving the bearing reaches about 40-48 C, start the circulating water through the oil coolers to maintain bearing oil temperature.

- Increase the speed gradually following the manufacturer's instructions.

- Adjust the water seal on the turbine and the atmospheric relief valve.

- Once the machine comes under the control of governor, test the emergency governor by opening the valve in the oil line to it. See that all valves controlled by this tripping mechanism close promptly. Reset open throttle valve and restore speed to normal.

- Close all drains.

- Open leak off from H.P. side gland in order to flow any excess steam to the filled water heater or to one of the lower stage of the turbine.

- Synchronize the generator and tie it in the line.

- The speed is now under the control of governor. The turbine is now ready for load and is regulated from the turbine control panel.

by Unknown · 0

From the theoretical point of view, a turbine rotor is a balanced body but in actual practice, errors of balance are introduced by various causes such as:

- Lack of homogeneity of material

- Slight error in machining.

- Difference in pitch of blades and also in individual masses

Therefore, it is essential to test balance of a complete turbine rotor and make any adjustments necessary to ensure that the balance is as good as possible. The purpose of balancing of rotors is to reduce the amplitude of vibration on a tolerable level which can be taken to be about 0.0254mm at the bearing pedestrals of a 300 rpm machine. There are two types of balancing- Static and dynamic.

1. Static Balance:

It means that the weight of the rotor is evenly disposed around the axis of the shaft. It is checked by rolling the rotor on horizontal knife edge supports.

2. Dynamic Balance:

It means that the moments of the out-of-balance weights along the axis about either bearing add upto 0. It is checked by spinning the rotor on resilient bearings detecting the vibration and adding or subtracting weights untill the vibration is negligible.

Normally, rotors are balanced at 400 rpm. The adjustment in weight is made in two planes, one at each end of the rotor by varying screwed plugs in tapped holes, or by removing metal from portion of a rim added for this purpose, or by fixing weights in a groove by means of screws. Preference is given to subtraction of weights instead of addition, since there is a chance of coming the loose weights drift.

by Unknown · 0

Types of Rotors:

There are 5 types of steam turbine rotors:

- The built-up rotor

- The integral rotor

- The hollow drum rotor

- The solid drum rotor

- The welded disc rotor

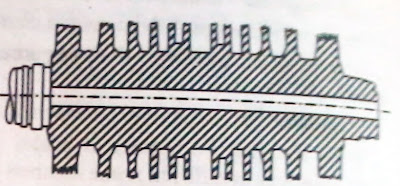

1. The Built-up Rotor:

It consists of forged steel shaft on which separate forged steel discs are shrunk and keyed. It is cheaper since the disc and shaft are relatively easy to forge and inspect for flaws and machining of these components can be carried out concurrently. Its shaft is machined with a series of stepped diameters ending with central collar. Each disc is heated and assembled on the shaft in turn, each being held in position by a form of circlip. Relative rotation is prevented either by keys, or by hub dowels known as buttons, which locate the hubs one to another to the central collar. The number of discs depend upon the number of stages which in turn depends upon the turbine output.

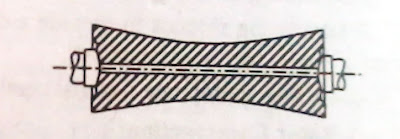

2. The Integral Rotor:

The shaft and wheels of this type of rotors are formed from one solid forging. Integral rotors are expensive and difficult to forge, and there is a high incidence of rejects. Over and above, a large amount of machining time and waste material are involved.

Nevertheless, the advantages are such that the are invariably used for the H.P. (high pressure) rotors on modern re-heat turbines, and sometimes for the I.P. and L.P. rotors as well. Following are the advantages of integral rotors:

- There is no chance of disc to become loose, particularly at high temperature end where at times the wheels may be hot and the shaft pull as found in the built-up rotor.

- This rotor is also free from the effect of creep which may cause the shrink fit of built-up rotor to disappear after a large number of running hours.

- The hoop stress is of lower magnitude as it contains a small hole meant for inspecting the forging.

- There is saving in axial length and reduction in spindle diameter over the built-up type.

3. Hollow Drum Rotor:

This type of rotor promotes even temperature distribution because it is designed with the same thickness of material as the casing.

4. Solid Drum Rotor:

This type of rotors are suitable for cylinders where there are lower temperatures but large diameters, as in I.P. cylinders without re-heat.

5. Welded Disc Rotor:

The last stage disc is the most heavily stressed part of the turbine and this is one of the main problem of L.P. rotor. The centrifugal load of the large rotating blades set up a tensile stress in the rim of disc, and this stress increases with decreasing radius, its maximum value being at the bore of the hub. If the bore is exceedingly small, the hoop stress becomes very less but of there is no hole, the hoop stresses throughout the disc are theoretically halved. Since there is no central hole in welded disc rotor, it suitable for L.P. rotors. It has two main advantages: It is less stressed and no need for large shaft forgings which are expensive and difficult to manufacture. The welding process and subsequent heat treatment should be performed with great attention.

by Unknown · 0

Sunday, 19 August 2012

The attachment of the turbine blades to the rotor is the most critical aspect of steam turbine design. All the forces are transmitted through the attachment to the rotor. Specially, at the low pressure end of turbines of large output, the attachment has to bear a relatively large forces due to high speed, the centrifugal force on the blade is many times its mass. Therefore it becomes necessary to estimate the stresses in the attachment but sometimes it is difficult to get the exact value. There is always the possibility of stress concentration at the sharp corners. Therefore, selection of material is very important which can safeguard from this stress concentration and that is why the calculated stress is kept reasonably low. A careful study of the forms of attachment is also necessary because occasionally it influences the shape of the wheel, rim and stresses in the disc. The form of the attachment should be such that the centrifugal force on the blade is transmitted to the disc in the simplest and most direct manner and it should give the security of attachment.

The various forms are:

The various forms are:

- De-Laval Blade root attachment

- Inverted-T attachment

- Serrated blade root arrangement (Annular fir-tree)

- Attachment for high pressure Crutis wheel

- Straddle attachment

- Modified straddle attachment

- Side entry blades attachment

- Shrouding strip attachment

- Parson's end tightened blading

- Parson's integral blades

Most of the above attachments are also used in gas turbine blading however annular fir-tree or its modified versous are most common.

Sunday, 19 August 2012 by Unknown · 0

Stiffness against vibration and correct guidance to the steam is essential. To meet these conditions the outer ends of the blades are usually tied together by a perforated ribbon of metal known as Shroud. In case where stress consideration is of primary importance, for example, the last row of the low pressure blades, the shroud is omitted. In longer blades of LP turbine, lasing or binding wires are also silver soldered to connect bundles of blades together at various radii.

by Unknown · 0

Production of Blades

Blades may be considered to be heart of turbine, and all other members exist for the sake of blades. Without blading, there would be no power and the slightest fault in blading would mean a reduction in efficiency or lengthy and costly repairs.

The following are some of the methods adopted for the production of blades:

- Rolling - Sections are rolled to the finished size and used in conjunction with packing pieces. Blades manufactured by this method do not fail under combined bending and centrifugal force.

- Machining - Blades are also machined from rectangular bars. This method has more or less same advantage as that of rolling. Impulse bladings are manufactured by this technique.

- Forging - Blade and vane surfaces having air foil sections are manufactured by specialist techniques. The simplest way is to determine the profiles required at the hub and tip, and join them by straight, ruled lines. For more accuracy, a profile, at middle to each end separately is obtained. Once the geometry of the family of the ruled lines is established they may be machined in turn by milling machine, rest carefully for each line to generate the shape required in a master blog from which the forging die may be copy-machined. This method ensures the accurate forging of blades to their finished size, requiring only fletting and polishing. The machining of the fir-tree root is often done by broaching, and electrochemical machining may be used in some parts to avoid the conventional cutting processes. In advance method, computers are used to determine the blade shape required by aerodynamic and stress criteria. The computer may then instruct a numerically controlled milling machine to prepare the dies.

- Extrusion - Blades are sometimes extruded and the roots are left on for subsequent machining. This method is not as reliable as rolled section, because of narrow limits imposed on the composition of the blade material.

- Cold Drawing - Blades are also cold drawn.

by Unknown · 0

Hollow blades satisfy the condition for ideal blades ie they give the most efficient control to the steam and are at the same time uniformly stressed . The hollow blades do not impose severe stresses in the rotor, and for that reason increased speed, leading to increased output is possible.

by Unknown · 0

The blades of low pressure stage must be long to cater for the greatly increasing specific volume of steam at the lower pressures. Irrespective of the design of previous stages, the final stage of LP turbine employ little or no reaction at the root and up to about 65% reaction at the tip, this design allows the steam velocity to match the peripheral blade velocity of all radii. in order to dampen vibration long blades may be lased together in batches. It is to be noted that the lasing holes are source of weakness and disturbs the flow path, so it should be avoided as far as possible by better designing against vibration. Sometimes an arched cover bend may be used to brace the blades instead of lacing wires.

LP stage bladings face an another problem of erosion of leading edges due to condensation droplets. In order to avoid this, satellite protection strips which is extremely hard alloys of cobalt, chromium, tungsten and carbon are sometimes braced to the leading edges due to centrifugal action much moisture can be extracted after leaving the moving blades, and provision is made in the cylinder to lead this water away.

Sometimes multi exhaust is used to reduce the length of LP stage bladings invariably, double flow LP turbines are used. A long blade is not suitable because of the following reasons:

Sometimes multi exhaust is used to reduce the length of LP stage bladings invariably, double flow LP turbines are used. A long blade is not suitable because of the following reasons:

- The blade speed varies from root to tip thus there is different blade angles, and if the steam is to flow on the blade without shock, the blade must be twisted. Generally the discharge is axial, they are mainly impulse form at the roots and reaction form at the tips. The inlet angles of blades are varied to allow for change in blade speed.

- The space between the adjacent blades may increase so much from the root to the tip as could affect adversely the steam flow through the blades.

- At the tip speed of 330m/s the stress at the root of blade is great. For this reason and from the point of view of stability, low pressure blades are not made longer than 1/3rd the drum diameter and even then, the blade section is frequently tapered from the tip to the root.

by Unknown · 0

Design requirements of nozzle:

- The design of nozzle should be such as to permit easy manufacturing and finishing and allow accurate channel sections to be obtained specially at the high pressure end of the turbine.

- The inlet of the nozzle should be so designed as to utilize the carry over energy from the previous stage to the largest possible extend.

- There should not be any sudden change in the direction of flowing steam, specially at high velocity.

- The shape and finish of the nozzle should be designed so that the conversion of thermal energy into kinetic energy should take place with greatest possible efficiency.

- In order to reduce friction, specially when the steam velocity is high, the valve surface should be as smooth as possible.

Construction of convergent nozzle:

First Stage Convergent Nozzle:

This segment consists of 6 nozzles and comprises a casting 'a' into which the nozzle guide vanes 'b' are embedded by 'casting in'. For casting of the guide vanes, they are first made from sheet metal of uniform thickness which is cut to save and then curved in press. With the correct shape and correct curvature at inlet, these are embedded in a sand core to form the steam passage. Then molten metal is poured into the mould which the projecting edges of the guide vanes are surrounded, on freezing of the metal, the vanes become firmly held and casting is taken out.

For this type of nozzle, rolled copper guide blades cast in gun metal nozzle segments are used for saturated steel. But for superheated steam steel or alloy steel must be used. In steel or alloy steel group materials such as low carbon, steel, 3-5% Nickel, stainless steel, Iron and hadfleld's hecla A.T.V. steel may be used.

Built-up Nozzle:

Built-up construction is shown in figure.

It provides an accurate nozzle segment. It consists of a number of vanes 'a', which are machined all over, and placed between curved angles 'b', likewise machined all over. The ends of segments are closed by pieces c of suitable shape. Through the rivets 'd' the guide vanes are attached to the angles. A small spigot 'e' is riveted over it.

It provides an accurate nozzle segment. It consists of a number of vanes 'a', which are machined all over, and placed between curved angles 'b', likewise machined all over. The ends of segments are closed by pieces c of suitable shape. Through the rivets 'd' the guide vanes are attached to the angles. A small spigot 'e' is riveted over it.

Diaphragm Nozzle:

A different type of built-up construction for high pressure diaphragm is shown in figure.

Each diaphragm contains a steel centre 'a', in halfes to which several nozzle elements 'b' are riveted as shown in figure. Each nozzle elements are machined all over to a fine finish.

Each diaphragm contains a steel centre 'a', in halfes to which several nozzle elements 'b' are riveted as shown in figure. Each nozzle elements are machined all over to a fine finish.

Construction Of Convergent-Divergent Nozzles:

De-Laval Nozzle:

It is a convergent-divergent type of nozzle made of gun metal as shown in figure.

The nozzle is fitted with a valve arrangement 'c' which opens or closes it to a steam chest 'a'. It is mostly used in experimental type of impulse turbine.

The nozzle is fitted with a valve arrangement 'c' which opens or closes it to a steam chest 'a'. It is mostly used in experimental type of impulse turbine.

Cast -in Type:

Cast-in type is shown in figure.

It is largely used in marine impulse turbine. Guide blades are rolled to the section shown by dotted lines in the upper part of figure, and then cut to shape and cast into the nozzle segment in the usual manner.

It is largely used in marine impulse turbine. Guide blades are rolled to the section shown by dotted lines in the upper part of figure, and then cut to shape and cast into the nozzle segment in the usual manner.

Built-up Nozzle:

Built-up nozzle is shown in figure.

It is made of steel to B.S.En 58B and is readily replaceable at any time. It consists of two parts- lower and upper forming rectangular cross-section. It is machined from a bar by employing jigs and fixtures to the required shape. It is used in many impulse turbines and another form of built up nozzles is also shown in figure.

It consists of 3 parts segment strips 'a' in which the nozzle passages are machined, a covering segment 'b' and a wedge piece 'c'. The locking screws 'd' on the ring 'c' causes the strips 'a' and 'b' to be forced against the steam chest. The cap nut 'e' covers the set screw 'd' so that there should not be any leakage. It is used in so many turbines.

It is made of steel to B.S.En 58B and is readily replaceable at any time. It consists of two parts- lower and upper forming rectangular cross-section. It is machined from a bar by employing jigs and fixtures to the required shape. It is used in many impulse turbines and another form of built up nozzles is also shown in figure.

It consists of 3 parts segment strips 'a' in which the nozzle passages are machined, a covering segment 'b' and a wedge piece 'c'. The locking screws 'd' on the ring 'c' causes the strips 'a' and 'b' to be forced against the steam chest. The cap nut 'e' covers the set screw 'd' so that there should not be any leakage. It is used in so many turbines.

by Unknown · 0

|

| (Image credit: sokeo.com) |

The aim of engineering science theory is to design and the ultimate aim of any design is to construct as per design so that the product maintains its high quality with minimum cost and requires minimum maintenance. This topic deals with construction of steam turbine components. The construction of rotor will also be application to gas turbines.

Here, we are discussing about the constructions of:

by Unknown · 0

Wednesday, 15 August 2012

Filler metal:

Filler metal:

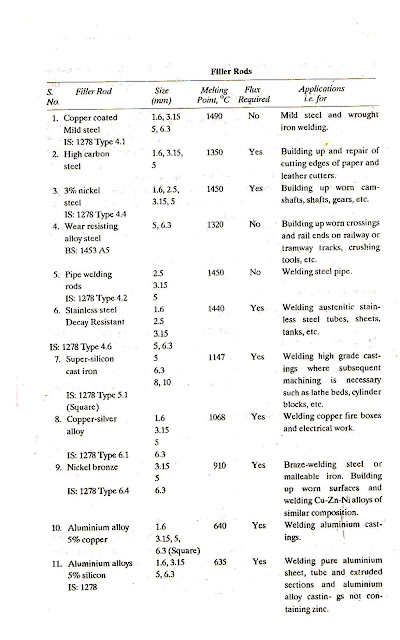

It is the material that is added to the weld pool to assist in filling the gap or groove. Filler metal forms an integral part of the weld. Filler metal is usually available in rod form. These rods are called filler rods. Filler rods have the same or nearly the same chemical composition as the base metal. Welding filler rods are available in a variety of composition and sizes. Some of them are given in the table below:

Flux:

During welding if the metal is heated or melted in air, oxygen from the air combines with metal to form oxides which result in poor quality, low strength weld or in some cases may even make welding impossible. In order to avoid this difficulty, a flux is employed during welding. A flux is a material used to prevent, dissolve or facilitate removal of oxides and other undesirable substances. A flux prevents the oxidation of molten metal. Flux may be used either by applying it directly on the surface of the base metal to be welded or by dipping the heated end of the filler rod in it. The flux sticks to the filler rod end. No flux is used in the gas welding of steel.

- Flux for welding cast iron: Fluxes for gray iron rods usually composed of borates or boric acid, soda ash and small amounts of sodium chloride,etc.

- Flux for welding stainless steel: Flux may contain compounds such as borax, boric acid, fluorspar, etc.

- Flux for welding aluminium and its alloys: The flux may be applied on the base metal by brushing and on the filler rod end by dipping the same into the flux paste just before welding. Fluxes employed for welding aluminium and its alloys are compounds of lithium, sodium and potassium and are obtainable in either paste or powder form.

- Flux for welding copper and its alloys: Flux is not necessary for gas welding of pure copper, however for copper alloys, borax based fluxes may be used.

- Flux for welding magnesium and its alloys: Flux must be applied to all edges to be welded and to the welding rod when welding magnesium and its alloys. A flux may contain sodium chloride, potassium fluoride, magnesium chloride, barium fluoride.

- Fluxes for welding nickel and its alloys: Gas welding of pure nickel requires no flux. However alloys of nickel such as inconel and monel require a flux to further clean the base metal and to break up the oxides that are formed as a result of the alloying agents. Flux for inconel may contain Ca(OH)2 , boric anhydride.

Wednesday, 15 August 2012 by Unknown · 0

Introduction to Gas Welding:

Gas welding is a fusion welding process. It joins metals using the heat of combustion of oxygen/air and fuel gas that is acetylene, hydrogen or butane. The intense heat or flame thus produced melts and fuses together the edges of the parts to be welded with the addition of a filler metal.

Oxy-acetylene welding:

When acetylene is mixed with oxygen in correct proportions in the welding torch and ignited, the flame resulting at the tip of the torch is sufficiently hot to melt and join the parent metal. The oxy-acetylene flame reaches a temperature of about 3200 C and thus can melt all commercial metals which, during welding, actually flow together to form a complete bond. A filler metal rod is generally added to the molten metal pool to build up the seam slightly for greater strength. The maximum temperature of the oxy-acetylene flame is 3100 to 3200 C and the center of the heat concentration is just off the extreme tip of the white cone. Combustion of gas mixture is recognized as taking place in two main stages:

- Stage 1: Oxygen and acetylene in equal proportions by volume burn in the inner white cone. The oxygen combines with carbon of the acetylene and forms carbon monoxide and hydrogen is liberated.

- Stage 2: Upon passing into the outer envelope of the flame two more reactions take place as combustion is completed. The carbon monoxide uses the oxygen supplied from the air surrounding the flame and as a result of burning forms carbon dioxide. The hydrogen also burns with oxygen from atmosphere and forms water vapour. It can be seen that about 2/5 of oxygen necessary for the complete combustion of acetylene is got from the cylinder whereas the rest comes from the surrounding air atmosphere because of the need for supplemental oxygen from the atmosphere, the acetylene oxygen flame cannot be used inside of pipes or structures subjected to oxygen depletion from gas welding. By varying the relative amounts of acetylene and oxygen in the gas mixture in the torch, a welder can produce different flame atmospheres and temperatures as he requires.

Flame adjustment:

- To start with, when the oxy-acetylene gas welding torch is ignited, it gives an acetylene flame in which enough oxygen is drawn in from the atmosphere to burn acetylene partially. From acetylene flame, abundance of free carbon is released into the air. An acetylene flame may be used to apply carbon to mold faces in the foundry, because the carbon acts as an insulator between the molten metal and the mold face.

- As the oxygen valve in the torch is progressively opened, the flame becomes generally luminous. Then the luminous portion contracts towards the welding tip, forming a distinct bright zone within a blue outer envelope. This is a carborising flame and has large excess of acetylene.

- With further increase of oxygen content, the bright zone of the flame contracts farther and is seen to consist of two parts: a brighter inner cone and a pale green feather trailing off its end into the blue envelope, this is reducing flame.

- If at this stage oxygen flow is increased gradually, a certain point will reach where one will notice a distinct change in the sound of the flame and a well-defined white cone will appear near the tip, surrounded by a bluish envelope that is faintly luminous. This is neutral flame. There is an approximate one-to-one mixture of acetylene and oxygen to result a neutral flame.

- Further increase of oxygen content into the mixture will give rise to an oxidising flame.

To extinguish the flame and stop welding:

- When the welding or cutting operation is finished, close the torch acetylene valve first and then turn off the torch oxygen valve.

- Close the oxygen cylinder valve

- Release the pressure in the hose and regulator by opening the oxygen control valve on the torch.

- Release the pressure in the oxygen regulator diaphragm by turning the regulator to the minimum pressure position.

- Close the oxygen control valve on the torch.

- Repeat the same procedure for purging acetylene.

by Unknown · 0

The chosen welding processes of practical significance in underwater welding are:

- Manual shielded meal arc welding, that is extensively used as a wet technique but is also suitable for habitate welding.

- TIG welding.

- MIG welding.

TIG and MIG welding processed have also been used to a limited extend for wet welding as well as more commonly in local enclosed gas shrouds.

1. Shielded metal arc welding:

Manual shielded metal arc welding is an economical process for underwater welding. This process can be carried out in all positions with the same success as welding in air. The DC welding equipment used for underwater welding must have a capacity of at least 300 Amps for each welder. All electrical leads, lighting gear, electrode holder, gloves, etc must be fully insulated and in good condition. Ferritic electrodes with a coated based on iron oxide should be used as they resits cracking, Positive polarity of work is preferred. This means that 65% to 75% of the heat is in the metal being welded. The weld pool is easier to handle and has enough fluidity to fill in undercut to a large extend. Electrode having positive polarity may have to be used for overhead butt-welding or welding cracks in the vertical and overhead positions. Current setting for underwater welding are normally higher than for welding air because there is a loss of heat by conduction through water and the control of these settings must be accurate to ensure consistent work.

2. TIG welding:

TIG welding has got the advantage that it gives a stable arc and less porous welds. TIG welding has been widely used, particularly for root runs. Although this process is relatively slow, it is very flexible and can accommodate variations in fit up and produce high quality penetration beads. TIG welding is preferred to MIG welding in dry welding as filler wire is manually controlled.

In TIG welding, as the depth (ie pressure) increases:

- The arc becomes constricted and the voltage increases for a given arc length.

- Tungsten tip starts getting eroded and this phenomenon influences weld bead width, and penetration. The erosion of the tip gives rise to arc instability when TIG welding is carried out at high pressure.

- Arc welding becomes more difficult.

TIG welding becomes restricted as the operating depth is increased.

3. MIG welding:

Because of the high cost of diving operations, it is highly desirable to complete welds in the shortest possible time. This has directed attention to the use of semi-automatic processes using solid wires or flux code wires. Wires containing oxidising and reducing elements give good results even without shielding. MIG welding is faster and less expensive that TIG welding. Arc heat increases with the depth of water so filler metal melts fast CO2 or Argon is used as shielding gas. The shielding gas gets denser and may require flow rates upto 10 times the surface rates. MIG dry welding is preferred to MIG wet welding for better results.

by Unknown · 0

International interests to develop and utilize oceans which cover 70% of the earth and its resources such as development of offshore gas and oil field, fisheries multiplication, large offshore construction and mineral resources, mining in the sea bottom,etc; have let to the development of underwater welding. Underwater welding has been used for temporary repair work caused by ships collisions, unexpected accidents, corrosion and other maintenance works.

Types of Underwater Welding:

Following are the types of underwater welding:

1. Wet welding

2. Dry welding :

1. Hyperbaric welding

2. Cavity welding

by Unknown · 0

Saturday, 11 August 2012

|

| Cam and follower (Image credit:cnx.org) |

A camshaft is simply a shaft on which cams are mounted. The camshaft is mounted in bearings in the lower part of the cylinder block in most inline engine. In few engines, it is located on the cylinder head. A cam is a device that changes rotary motion of the camshaft into linear motion of the follower or lifter. The cam has high spot or love the follower riding on the cams will move away from or toward the camshaft as the cam rotates. A camshaft is responsible for opening the valves. A camshaft has a number of cams along the length, two cams for each cylinder, one to operate the inlet valve and the other the exhaust valve. The camshaft is driven by the crankshaft either by a pair of meshing gears or by means of a pair of timing sprockets connected by a chain. The camshaft turns at half the speed of the crankshaft. The gear and sprocket maintain a definite time relationship between the camshaft and the crankshaft to ensure opening the valves exactly at the correct time in relation to piston position.

Saturday, 11 August 2012 by Unknown · 0

|

| Valve (Image credit: rexresearch.com) |

Valve is a device to close and open a passage in motor vehicle engines. Two valves are used for each cylinder - An inlet or intake valve and an exhaust valve. Fuel is admitted to the cylinder by the inlet valve, and the burnt gases escape from the exhaust valve. When closed, the valve must seal the combustion space tightly. The valves are usually made of Austenitic stainless steel which is a corrosion and heat resisting material. Exhaust valve is usually made of silchrome steel which is an alloy of silicon and chromium with unusual resistance to heat. Inlet valve being subjected to less heat is usually made of nickel chromium alloy steel. The valves used in modern passenger car engines are termed as poppet or mushroom valves.

Valve mechanism:

Valves are operated by cams mounted on a camshaft. The camshaft gets motion from crankshaft. As the camshaft turns the cam operates the valves. According to the location of the valves, the valve mechanism are of two types:

- Valve mechanism for operating the valve in engine block ( Straight poppet valve)

- Valve mechanism for operating the valve in cylinder head ( Overhead poppet valve)

by Unknown · 0

Flywheel is a heavy steel wheel attached to the rear end of the crankshaft. The size of the flywheel depends upon the number of cylinders and the general construction of the engine.

|

| Flywheel (Image credit: casting quality.com) |

The flow of power from the engine cylinder is not smooth although the power impulses in a multi-cylinder engine overlap or follow each other to provide a fairly even flow of power, however additional leveling off of power impulse is required. This is done by a flywheel. To understand the function of a flywheel in a better way, take the example of a four stroke, single cylinder engine. There are times when more power is being delivered than at other times. This tends to make the crankshaft speed up and then slow down. The engine delivers power during one stroke only - the power stroke and it absorbs power during the other three strokes - to push out the exhaust gases, to intake fresh charge in the cylinder and to compress this charge. Thus during power stroke, the engine tends to speed up and during the other three strokes, it tends to slow down. The inertia of the flywheel tends to keep it running at constant speed. When the engine tends to speed up, the flywheel resits it. When the engine tends to slow down, the flywheel resists it. Thus the flywheel absorbs energy as the engine tries to speed up and gives back energy when the engine tries to slow down, keeping the engine speed almost constant.

Flywheel is also used as a part of clutch mechanism and fluid drive unit. The flywheel also has a teeth on its outer edge to mesh with the electric cranking motor driven pinion when the engine is being cranked to start it.

by Unknown · 0

Crankshaft is the first part in the power transmission system onto which the reciprocating motion of the piston is converted into rotating motion with the help of connecting rod. A crankshaft consists of crank pin, crank arm, balancing weight and main journals. Big end of the connecting rod is connected to the crank pin of the crankshaft. Center to center distance between the crank pin and crankshaft is half of the piston displacement during a stroke. Thus one complete revolution of the crankshaft makes two stroke of the piston. The parts of the crankshaft inside the main bearings are called the main journals. The crankshaft is supported by the main bearings on the main journals. Balancing weights are provided on the opposite side of the crank arms for balancing.

|

| Crankshaft (Image credit: gasgoo.com) |

by Unknown · 0

|

| Connecting rod (Image credit: race.nangreaves.com) |

The connecting rod is the connection between the piston and the crankshaft. It joins the piston pin with the crank pin. Small end of the connecting rod is connected to the piston pin and larger end to the crank pin. The function of the connecting rod is to convert linear motion of the piston into rotatory motion of the crankshaft. The connecting rod usually has I-beam cross-section and made of forged steel. Aluminium alloy is also used for connecting rods. They are carefully matched in sets of uniform weight in order to maintain engine balance. The connecting rod carries the power thrust from piston to the crank pin and hence it must be very strong, rigid and also as light as possible.

by Unknown · 0

|

| Piston pin (Image credit: gasgoo.com) |

Piston pin or wrist pin or gudgeon pin connects the piston and small end of the connecting rod. Piston pin is generally hollow and made from case hardened steel heat treated to produce a hard, wear resisting surface. Piston pin may be selectively fitted and, if supplied with the piston, are not interchangeable. The external bearing surface is finished to a very high degree of accuracy to ensure correct fit in the piston and connecting rod. Piston pin should be inspected for wear, cracking or pitting. Circlips should always be renewed and where soft end pads are fitted, check that they are not loose or cracked. Circlips are types of rings which prevent pin to come in contact with cylinder wall.

by Unknown · 0

Piston rings are fitted into the grooves of the piston to maintain good seal between the piston and the cylinder wall. There are three functions of the piston rings.

- To provide a pressure seal to prevent blow-by of burnt gases. Blow-by is the name that describes the escape of burnt gases from the combustion chamber, past the piston, and into the crankcase.

- To form the main path for conduction of heat from the piston crown to the cylinder walls.

- To control the flow of oil to the skirt and rings themselves in adequate quantity while preventing an excessive amount reaching the combustion chamber with consequent waste and carbonization.

|

| Piston rings (Image credit: b2b-piston.com) |

Piston rings material:

Piston rings are usually made of fine grained alloy cast iron. This material possesses excellent heat and wear resisting qualities inherent in its graphitic structure. The elasticity of this material is also sufficient to impart radial expansion and compression which is necessary for assembly and removal of the ring, and particularly to enable it to exercise flexible pressure on the cylinder valves.

Types of rings:

- Compression rings

- Oil control rings

Compression rings seal in the air-fuel mixture as it is compressed, and also the combustion pressure as the mixture burns. There are two or three compression rings fitted into the top grooves. The number of compression rings tend to increase the compression ratio and oil control ring is fitted into the lower groove of the piston. Generally the second and third compression rings are taper-faced and supplied to improve oil sealing. Taper-sided compression rings are used to overcome ring-sticking problems in high output engines.

by Unknown · 0

|

| Piston (Image credit: btechgurus.blogspot.com) |

by Unknown · 0

There is problem of cylinder wear in I.C. engine and this is solved by use of cylinder liners. Cylinder liners are in the form of barrels made of special alloy iron containing silicon, manganese, nickel and chromium. They are cast centrifugally. It is now customary to fit cylinder liners on engines of cars and commercial vehicles. These liners are of the oil hardening type and offer considerably longer life for the engine.

The cylinder liners are of two types:

|

| Image credit: what-when-how.com |

1. Dry liners - Dry liner is made in the shape of barrel having a flange at the top which keeps it into position in the cylinder block. The entire outer surface of the dry liner bears against the cylinder block casting and hence has to be machined very accurately from the outside also. Thus it is not in direct contact with the cooling water and hence is known as dry liner. Its thickness ranges from 1.5mm to 3mm. It is used mostly for reconditioning warm cylinders.

|

| Wet cylinder liner (Image credit: what-when-how.com) |

2. Wet liners - A Wet liner forms a complete cylinder barrel. It is provided with a flange at the top which fits into the groove in the cylinder block. At the bottom either the block or the liner is provided with grooves, generally three in numbers, in which the packing rings made of rubber are inserted. The liner is in direct contact with the cooling water and hence is known as wet liner. The outer surface of the liner does not require accurate machining. Wet liners are thicker than dry liners, ranging from 1.5mm to 6mm.

by Unknown · 0

The bottom half of the crankcase is called the oil pan or sump. It is bolted or screwed to the lower flange of the main casting of IC engine and usually is made of pressed steel or aluminium. Oil pan serves as the reservoir for the storage, cooling and ventilation of engine lubricating oil.

The plane of the joint between the crankcase and the oil pan may be either on the level of the crankshaft axis or it may be lower. If it is on the level of the crankshaft axis, it will increase the bottom oil pan portion. If it is lower than this axis, it will increase upper portion of the crankcase thus increasing rigidity.

The oil pump in the lubricating system draws oil from the oil pan and sends it to all working parts in the engine. The oil drains off and runs down into the pan. Thus there is a constant circulation of oil between the pan and the working parts of the engine.

The plane of the joint between the crankcase and the oil pan may be either on the level of the crankshaft axis or it may be lower. If it is on the level of the crankshaft axis, it will increase the bottom oil pan portion. If it is lower than this axis, it will increase upper portion of the crankcase thus increasing rigidity.

|

| Oil pan or sump (image credit: autorepair.about.com) |

The oil pump in the lubricating system draws oil from the oil pan and sends it to all working parts in the engine. The oil drains off and runs down into the pan. Thus there is a constant circulation of oil between the pan and the working parts of the engine.

by Unknown · 0

Crankcase is attached to the bottom face of the cylinder block in I.C.engine. It acts as the base of the engine. It supports the crankshaft an camshaft in suitable bearings and provides the arms for supporting the engine on the frame. The oil pan and the lower part of the cylinder block together are called the crankcase.

|

| Crankcase with camshaft parts (Image credit: ultralightnews.ca) |

by Unknown · 0

In an Internal Combustion Engine, the top of the cylinder is covered by a separate cast piece known as the cylinder head. The cylinder head is bolted to the top of the cylinder block. It contains combustion chamber. Spark plug and sometimes valves are mounted in it. It incorporates passages for the flow of cooling water.

|

| Cylinder head (Image credit: dodgeram.info) |

by Unknown · 0

Friday, 10 August 2012

Cylinder block, cylinder head and crankcase are the main stationary bodies of the automobile engine. They serve as support and enclosure for moving parts. Nowadays the cylinder block and crankcase form a single casting which gives a rigid structure. Ribs are cast in the crankcase to give it extra strength and to support the main and camshaft bearings.

A cylinder block consists of three parts:

- The cylinders in which the piston slides up and down.

- The port or openings for the valves.

- The passages for the flow of cooling water.

Friday, 10 August 2012 by Unknown · 0

Internal Combustion Engine (I.C. Engine) is basically heat engine and converts heat energy into mechanical energy. I.C. engines are used mainly in the field of transportation but in many industries, farms; simplicity and low cost of operation are the determining factors in the adoption of I.C. engine. Internal Combustion Engine is that type of engine in which combustion takes place inside the cylinder itself. Air fuel mixture in case of petrol engine is compressed inside the cylinder and only air is compressed inside the cylinder in case of diesel engine and diesel is injected through injector and combustion takes place.

|

| Petrol Engine (Image credit:barclayphysics.wiki.com) |

|

| Diesel Engine (Image Credit: britannica.com) |

by Unknown · 0

Subscribe to:

Comments (Atom)